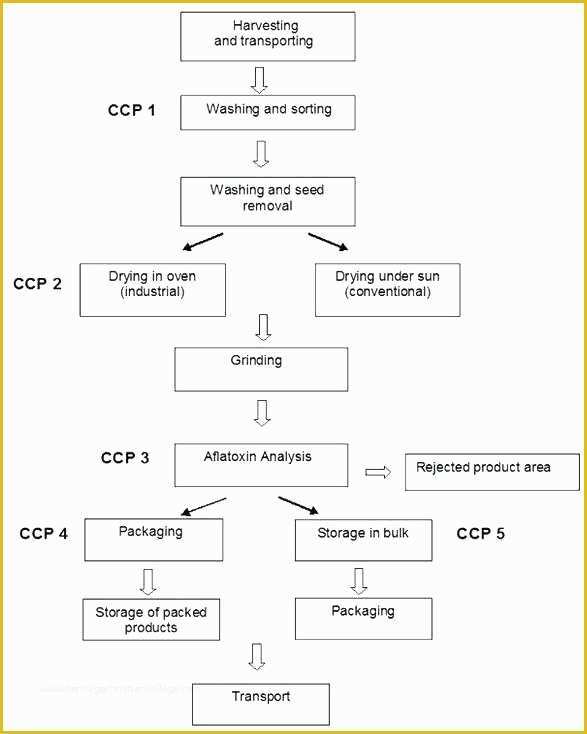

Establish record-keeping and documentation procedures.Ī HACCP plan is a food safety monitoring system that is used to identify and control biological, chemical, and physical hazards within the storage, transportation, use, preparation, and sale of perishable goods.Determine Critical Control Points (CCP’s).Determine Critical Control Points (CCPs) (Principle 2).Conduct a Hazard Analysis (Principle 1).Construct Flow Diagram to Describe the Process.Identify the Intended Use and Consumers.Establish the corrective action to be taken when monitoring indicates that a particular CCP is not under control.Establish a system to monitor control of the CCP.Determine the Critical Control Points (CCPs).How do you write a Haccp plan for a bakery? Use a HACCP system to control potential biological, physical, and chemical hazards that threaten the integrity of each of your food products. The Hazard Analysis and Critical Control Point (HACCP) system provides a systematic, globally-recognized approach to reducing safety hazards in food production systems. Therefore, cooking raw chicken can be identified as a CCP. Task 6 – Identify and analyse hazard(s) – (Principle 1)Įxample: Cooking raw chicken breast is the only step where bacteria can be eliminated or reduced to a level safe for consumption.Task 5 – On site confirmation of flow diagram.Task 4 – Draw up the commodity flow diagram.Task 3 – Identify the product’s intended use.What information is required in a complete Haccp plan?.

What are the 7 steps in creating a Haccp plan?.What is a HACCP plan and why would I need one?.What is an example of a critical limit for a HACCP program?.How do you write a Haccp plan for a bakery?.

0 kommentar(er)

0 kommentar(er)